WHAT IS SHOCK AND VIBRATION TESTING?

The purpose of shock and vibration testing is to evaluate the wide range of impacts that goods may experience during their distribution cycle. Shock tests and vibration tests have extremely exact qualities and can be executed freely or together inside a convention.

WHY IS SHOCK AND VIBRATION TESTING IMPORTANT?

Shock and vibration testing have an abundance of advantages. A test environment is used for shock and vibration testing to help simulate the conditions that a product might encounter over its lifetime. These tests are intended to guarantee that items are vigorous and secure during their interaction or travel. Performance issues and potential failures are identified through vibration testing before they occur.

Shock and vibration testing has the following advantages:

- Finding in the event that your product can endure use in reality

- Checking if your products agree with pertinent guidelines

- Stay away from exorbitant harm during transport

- Decreasing the number of returns and faulty products

- Having complete faith that the product will continue to function optimally

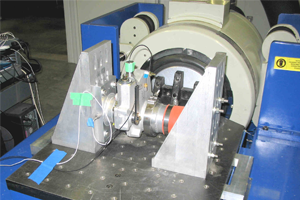

ARRAA LABS SHOCK AND VIBRATION TESTING FACILITIES:

We provide shock and vibration testing services in our ARRAA Labs in Chennai that utilize cutting-edge equipment to replicate low- and high-frequency conditions and to test items up to 2000 Hz. We can deliver NABL-accredited vibration testing and shock testing to the following standards: IEC BS EN 60068-2-6, IEC BS EN 60068-2-64, and IEC BS EN 60068-3-3.

Typical assessments for vibration testing include:

- Sinusoidal Vibration Test

- Broadband Vibration Test

- Broadband Random Vibration Test

- Broadband non-sinusoidal vibration test

- Shock and Bump Test

- Seismic Test