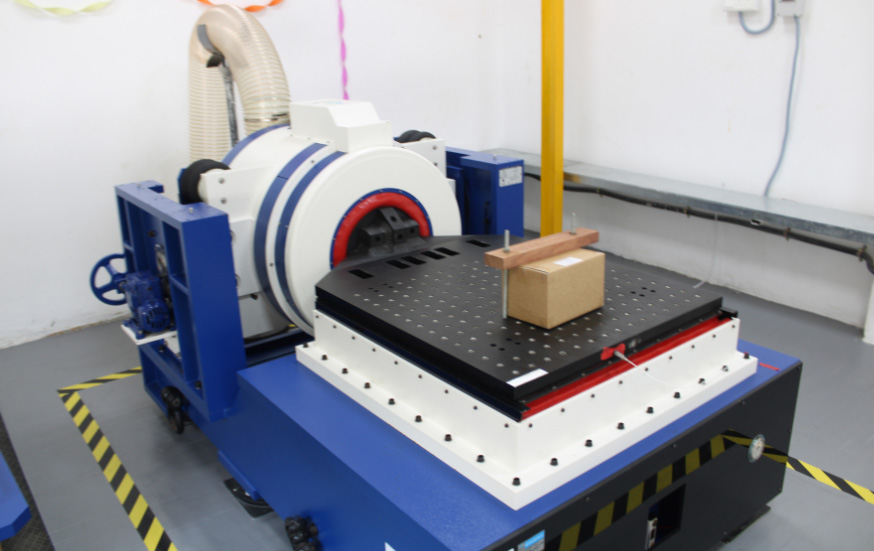

Shock and Bump Test

Mechanical shock testing takes a gander at the impacts of out of nowhere applied powers or sudden changes moving, which might upset working qualities or cause harm, especially in the event that the shock vibrations are redundant. A device’s suitability for use in electronic equipment that is subjected to moderately severe shocks from rough handling, transportation, or field operation can be determined through a mechanical shock test.

IEC 60068-2-27 is the standard that specifies test methods for Shock testing. We at ARRAA Labs provide testing services in accordance with IEC 60068-2-27:2008 and EN/BS EN 60068-2-27:2009. The test capabilities include acceleration levels of 5 to 10 g at 3, 6, 11, 16, 18, and 30 ms; 5 to 30 g at 3, 6, 11, 16, and 18 ms; and 5 to 50 g at 3, 6, and 11 ms.

Mechanical shock testing is the utilization of elevated degrees of speed increase, for an extremely brief timeframe, to a part, item, framework or construction to notice its reaction or corruption. Mechanical shock testing reproduces the consequences for a test of a speed increase beat that might be brought about by an effect, drop, blast, or other high sufficiency and brief length speed increase or deceleration. Mechanical shock tests have commonplace lengths of short of what one second for every shock, albeit various shocks throughout longer time spans are generally performed.

| Shock & Bump Test | |

|---|---|

| Parameter | Level |

| Lower Frequency(f1) | 0.2, 0.5, 1, 2, 4, 10, 20, 50, 120 Hz |

| Upper Frequency(f2) | 1, 2, 5, 10, 15, 20 |

| No of Shock | 3, 100, 500, 1000, 5000 |

| Duration of Pulse | 0.2, 0.3, 0.5, 1, 2, 3, 6, 11, 16, 18, 30 |

For personalized assistance, don’t hesitate to connect with our team at (+91) 90433 23091. Alternatively, you can share your specific requirements via email at enquiry@arraalabs.com. At ARRAA Labs, our dedicated team specializes in delivering high-quality lab services tailored to your needs. Reach out today and experience excellence in testing, inspection, and certification.

ARRAA Labs, an EMI/EMC, Environmental, and Vibration Testing company, is an independent NABL testing laboratory that performs inspection, certification, and testing for all kinds of industries that manufacture mechanical, electrical, and electronic products.